Portfolio

I've built many things in my life. This portfolio represents a small sampling of my work.

See also my resume here.

Solar Powered Farming Robots - 2019-Present

For Twisted Fields I have designed and fabricated multiple solar powered farming robots including all mechanical design, plasma cutting, welding, and fabrication, a full python software stack and database server with web UI, a complete set of electronics including motherboard, motor controllers, and induction steering sensors, wrote motor control and CAN bus code, and even worked with Linux kernel developers to update the CAN-ISOTP kernel module and back port it to the current raspberry pi kernel. I also wrote, filmed, performed in, and edited all of our youtube videos while managing a non-profit donation campaign which took in over $5000 in donations.

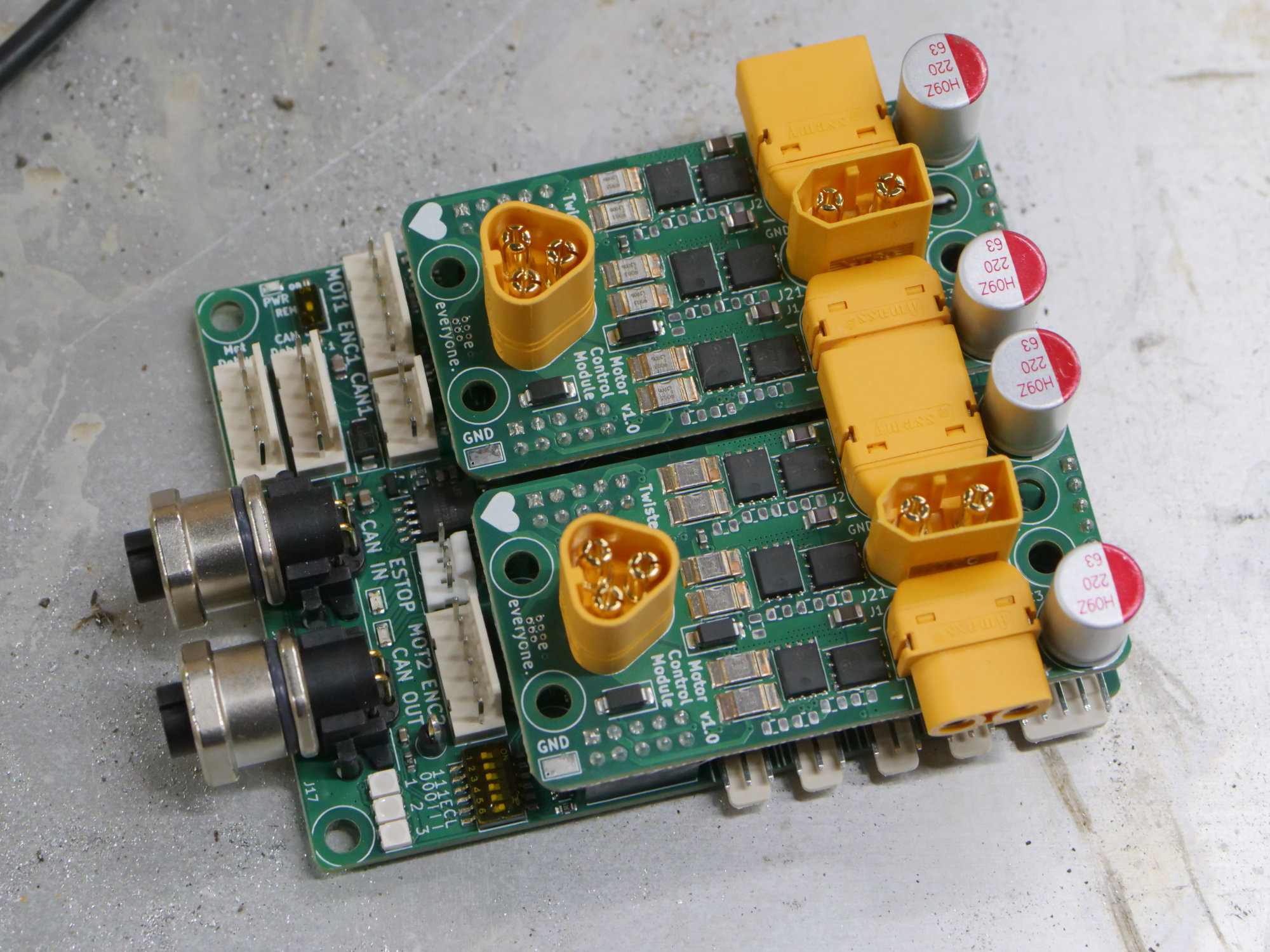

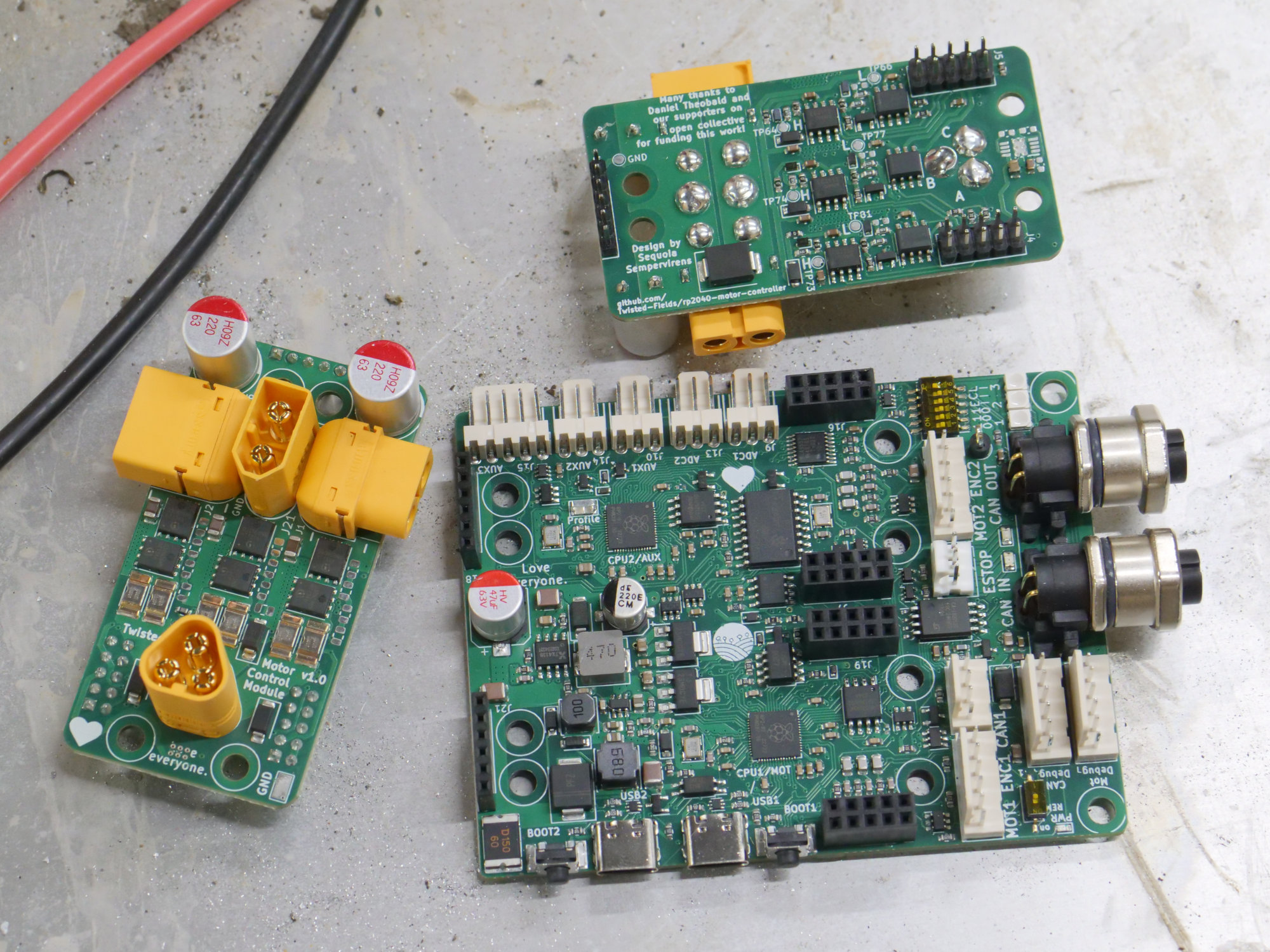

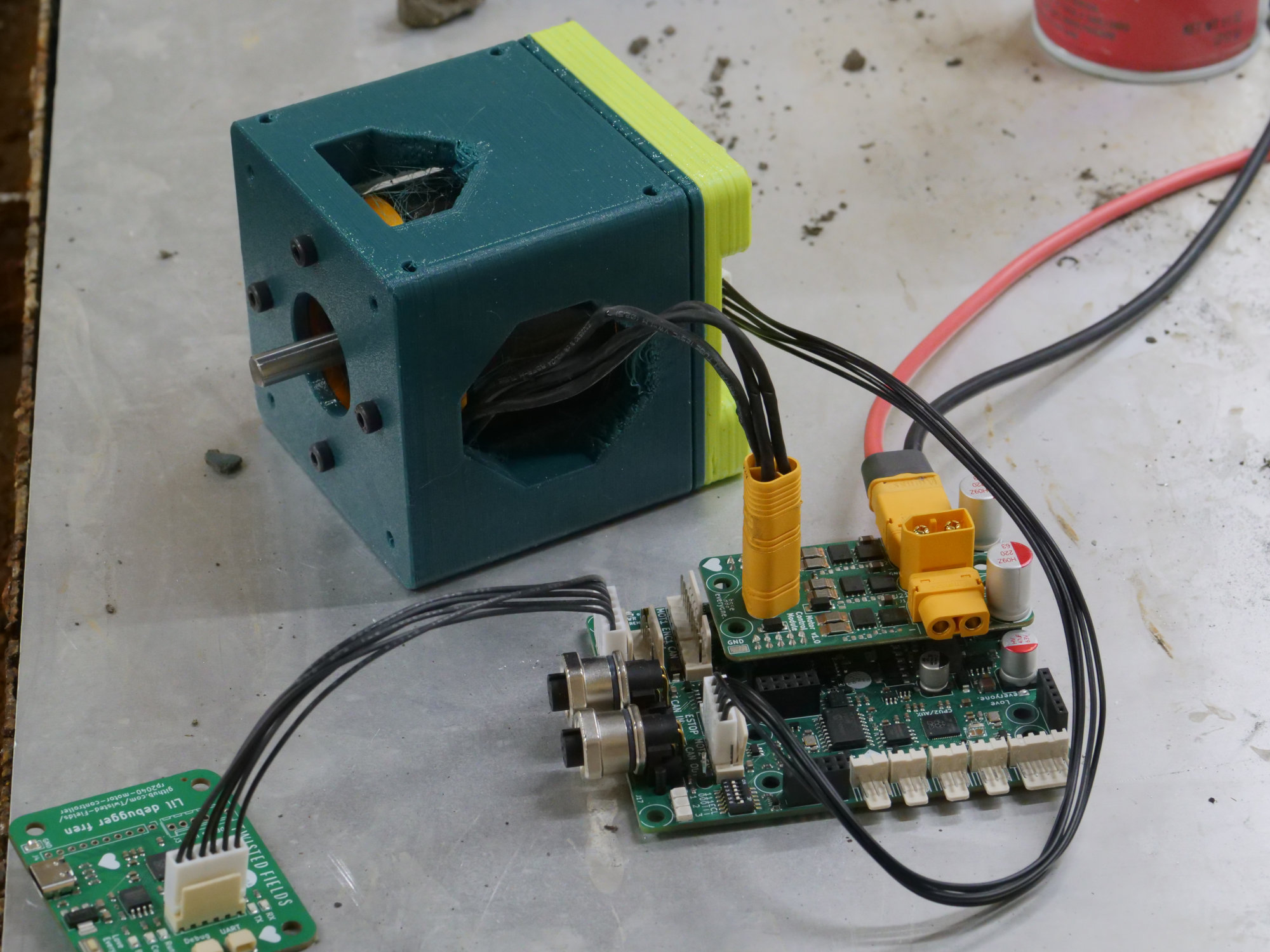

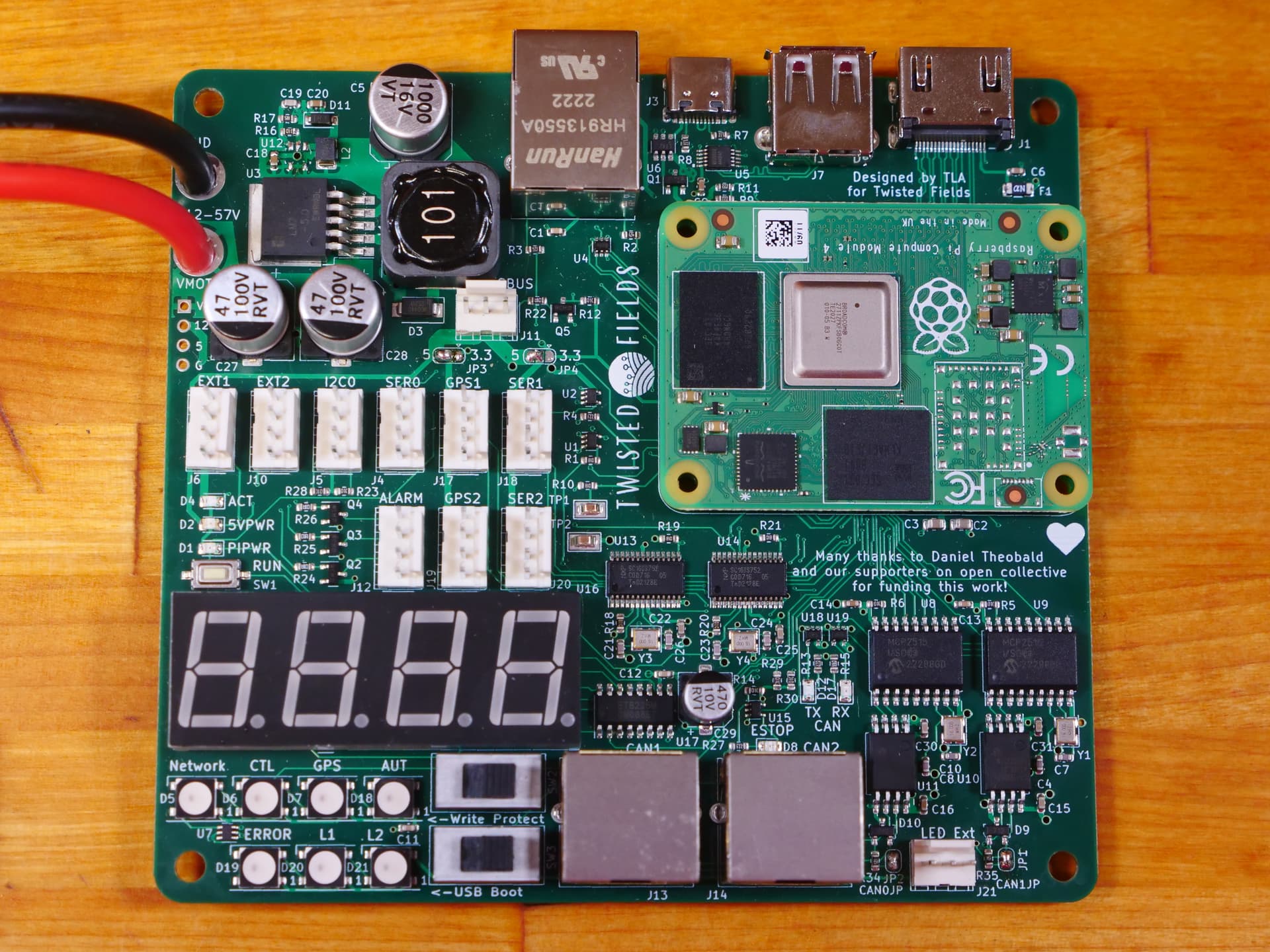

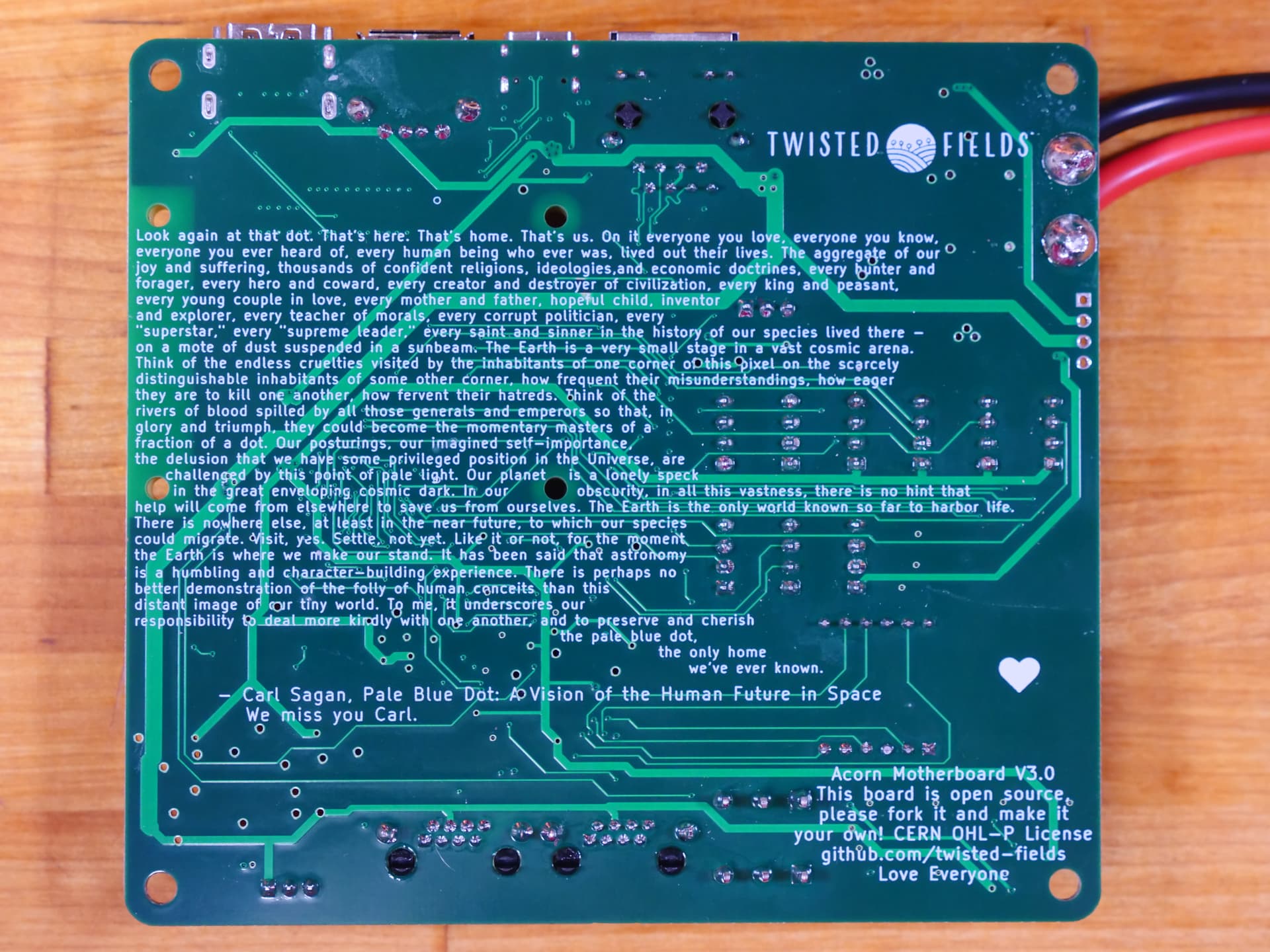

Farm Robot Electronics 2020-Present

The electronics for the robot include a dual brushless motor controller (60V 50A) with CAN bus and custom emergency stop circuit, as well as a Raspberry Pi CM4 (compute module) based motherboard.

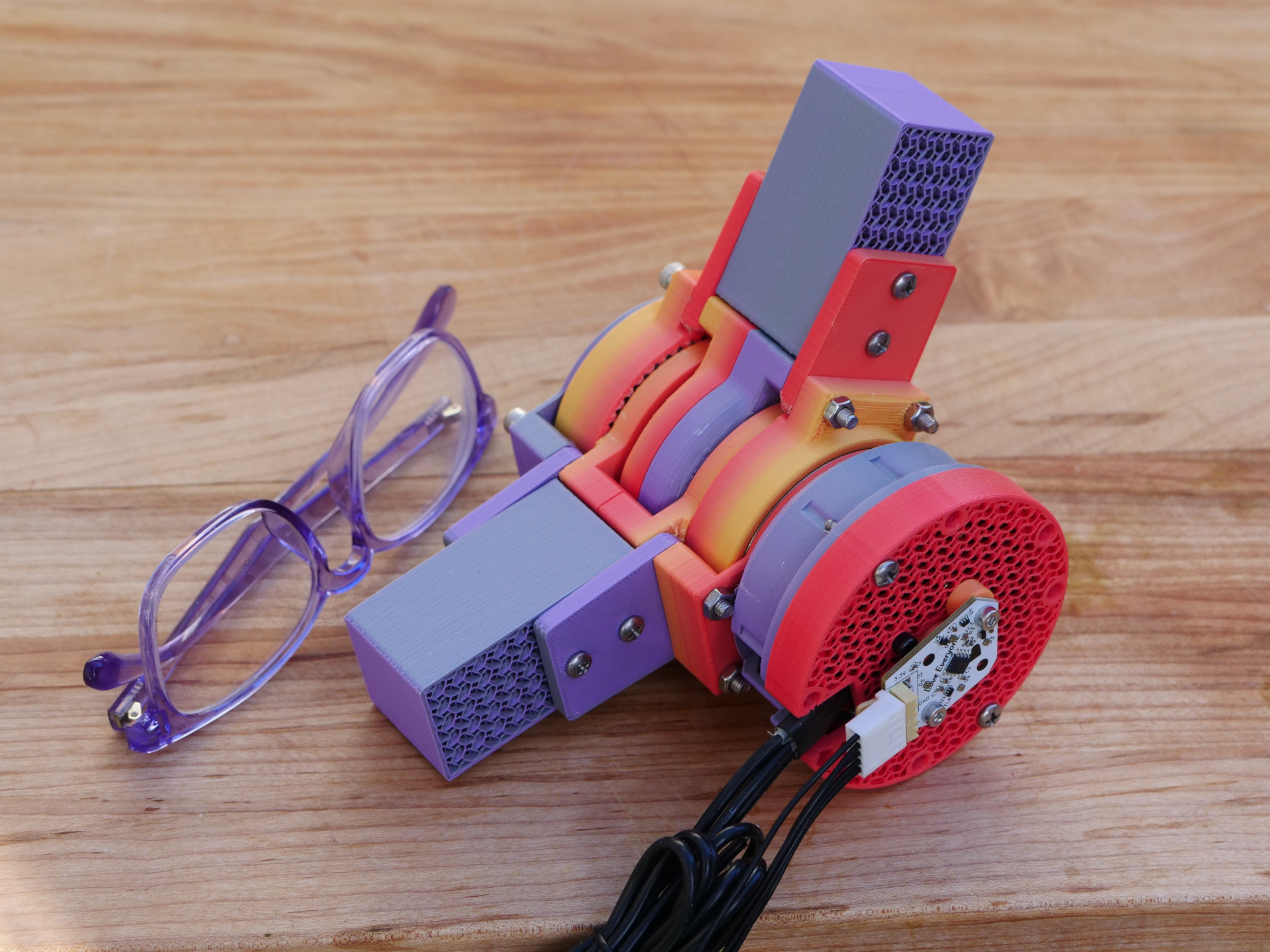

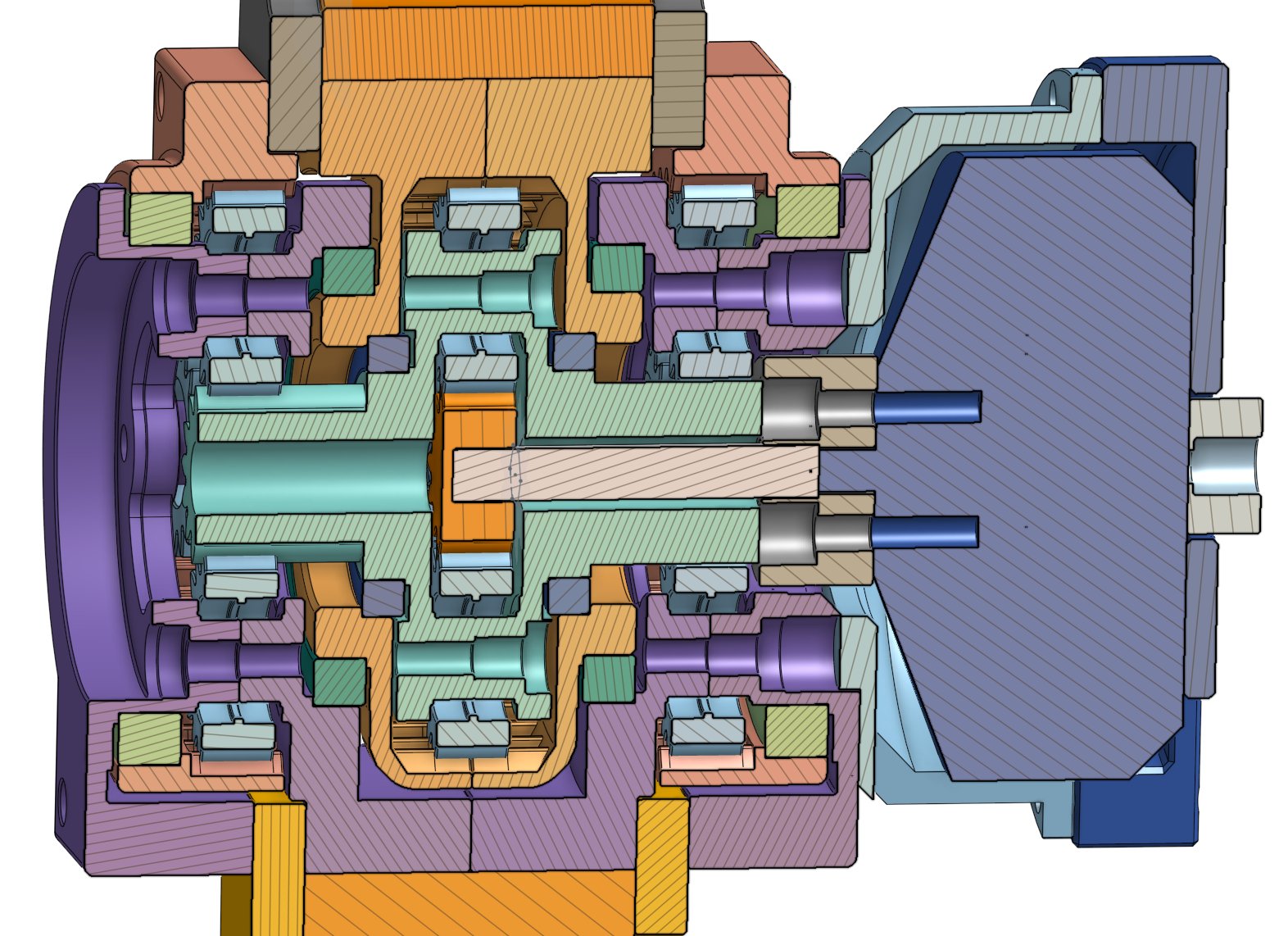

Novel planetary gearbox exploration - 2024

In 2024 I further explored concepts I first invented in the robot arm immediately below. Specifically I designed a single compact actuator that is easier for others to reproduce than a four axis arm, and I designed the parts to be 3D printable in stainless steel for a few hundred dollars. This actuator is based on my concept of a two stage planetary gearbox with dual second stages flanking a central first stage, whose sun gear is driven by a shaft that passes through one of the second stages to a side mounted drive motor. This configuration better balances forces in robotic joints like elbows and knees, and is based on my many years of experience designing custom 3D printed planetary gearboxes.

Four axis brushless robot arm - 2021

In 2021 I designed a four axis brushless motor powered robot arm with four custom 3d printed planetary gearboxes. The arm relied on several unique gearbox design concepts, including parallel second stages fed by a central first stage, and unified gearbox and frame members rather than gearboxes bolted to frame members. The parallel second stages flanking the first stage are I believe a novel gearbox configuration. That is to say, I think I invented a new kind of planetary gearbox well suited to knee and elbow style joints. I published the designs as open source.

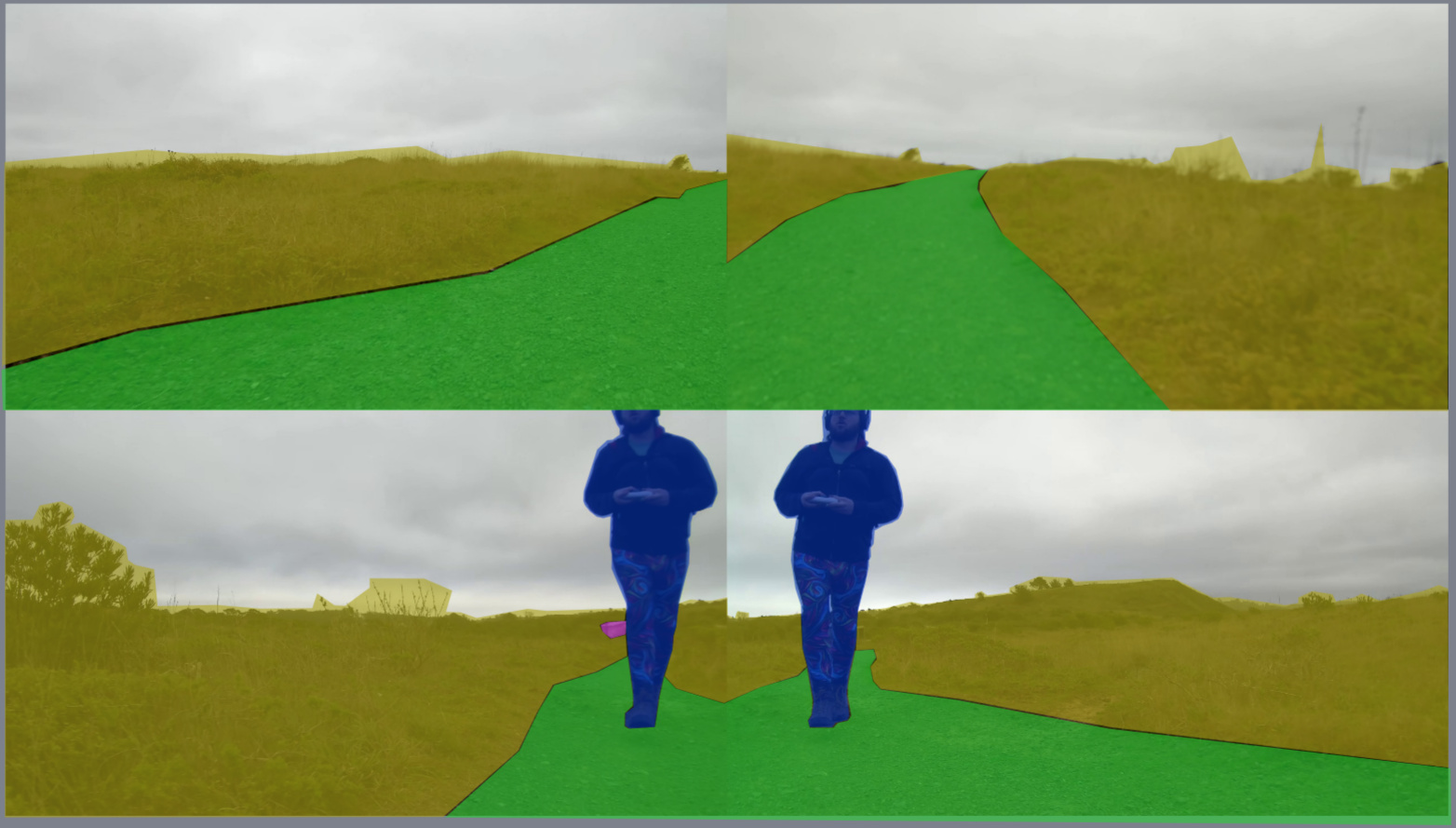

Rover 3D Printed Off Road Vehicles - 2017-Present

When work at Google was focused on software, I had to get some hardware time by building Rover, a 3D printable off road robot sturdy enough to carry a computer vision research payload. Rover includes a 52 megapixel four camera system with shutter synchronization and an NVIDIA Jetson Xavier machine learning computer. I collected images from Rover's camera system, hand labeled 150 images for image segmentation, and trained a machine learning model to identify trail vs foliage in off road environments. An interesting next step would be to compute a Bird's Eye View of the scene using this data. Rover is also an excellent rock crawler.

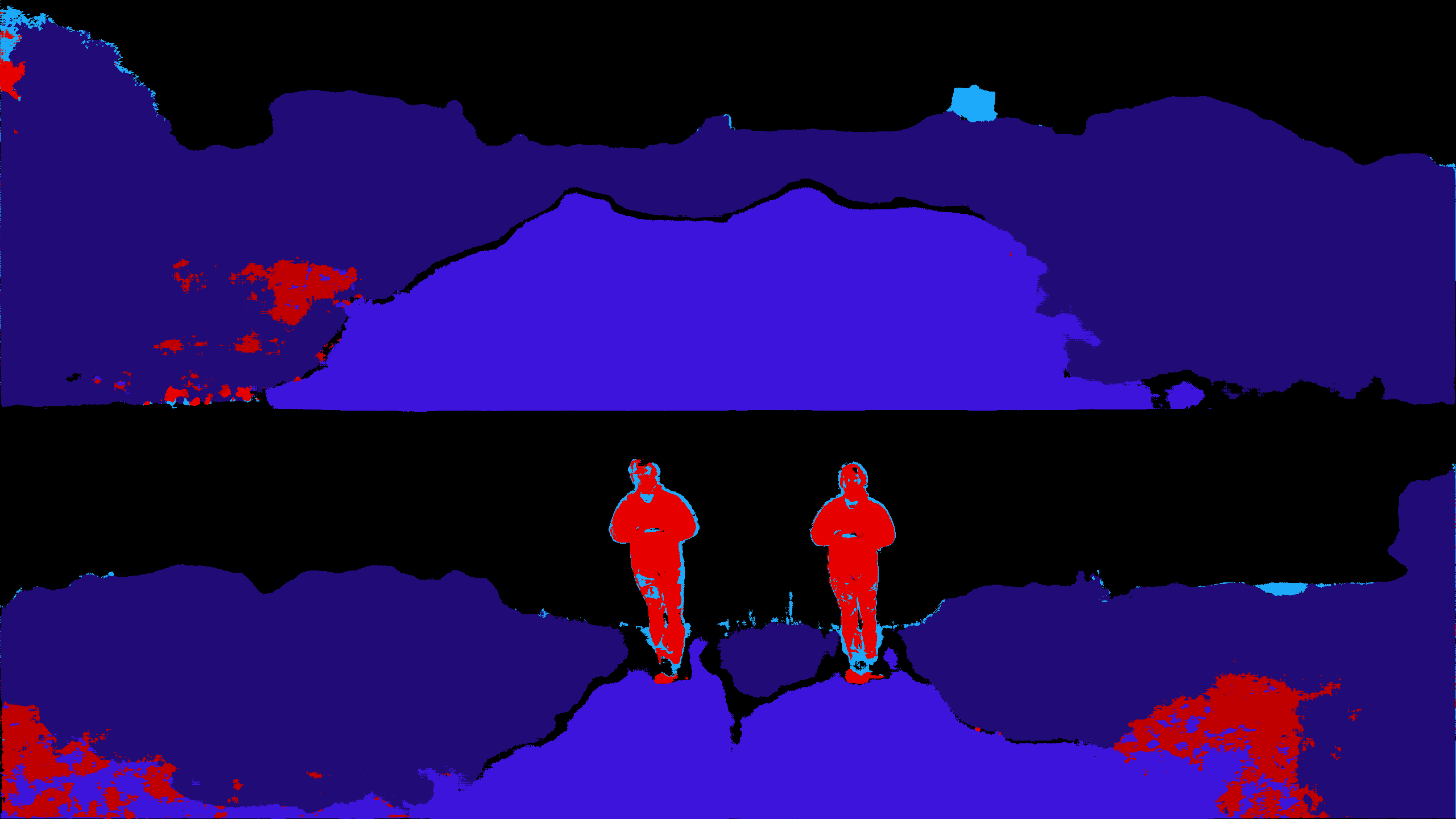

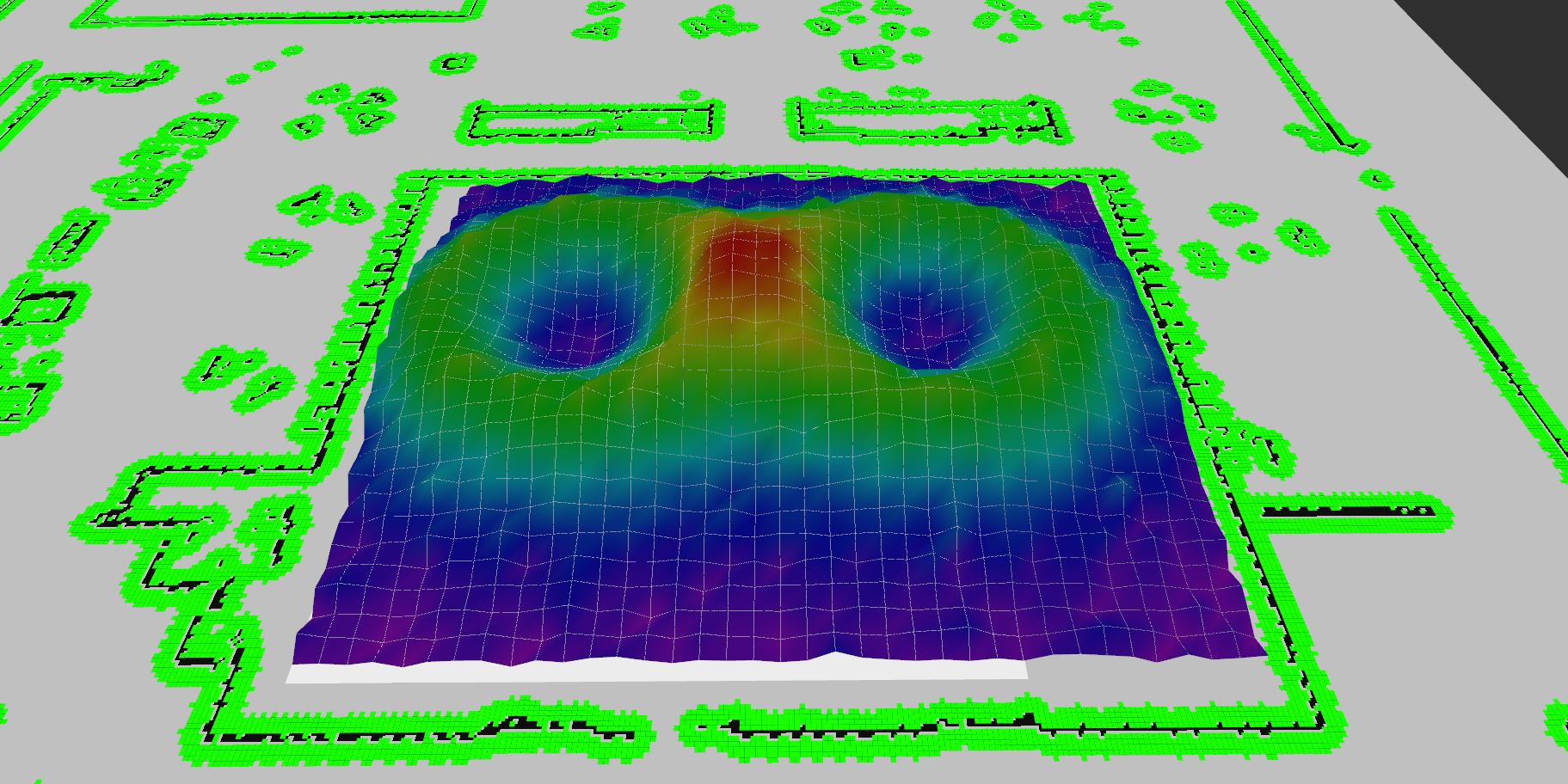

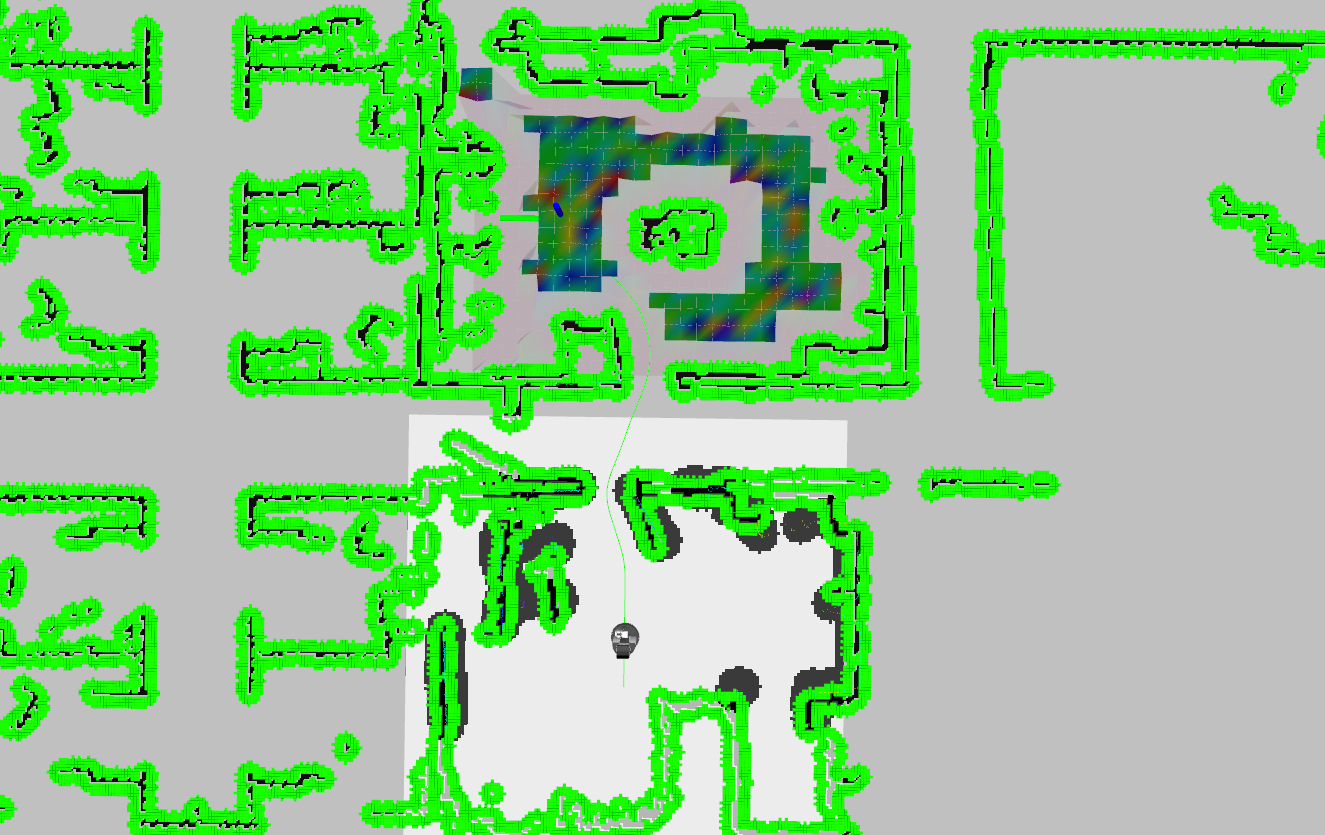

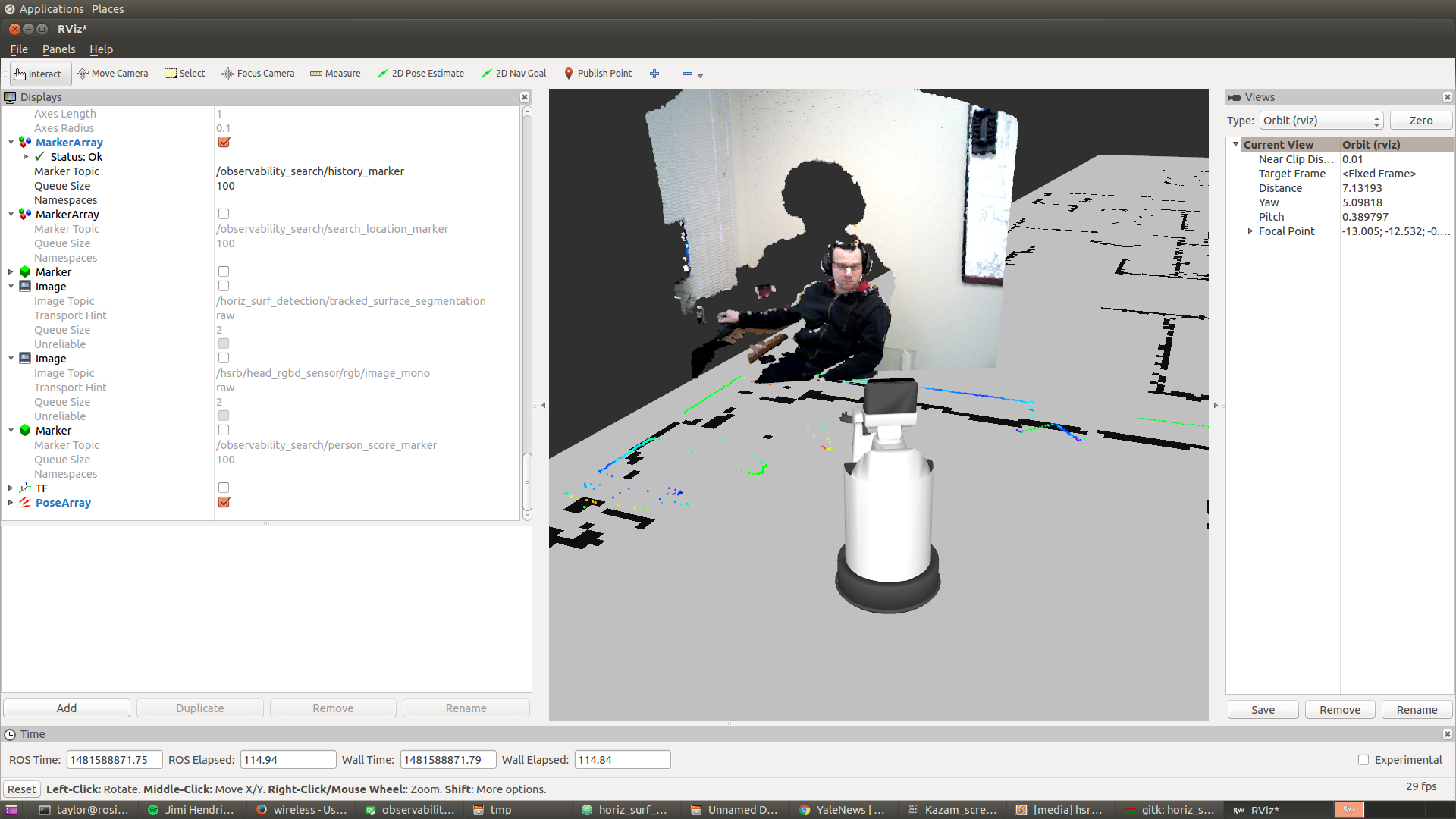

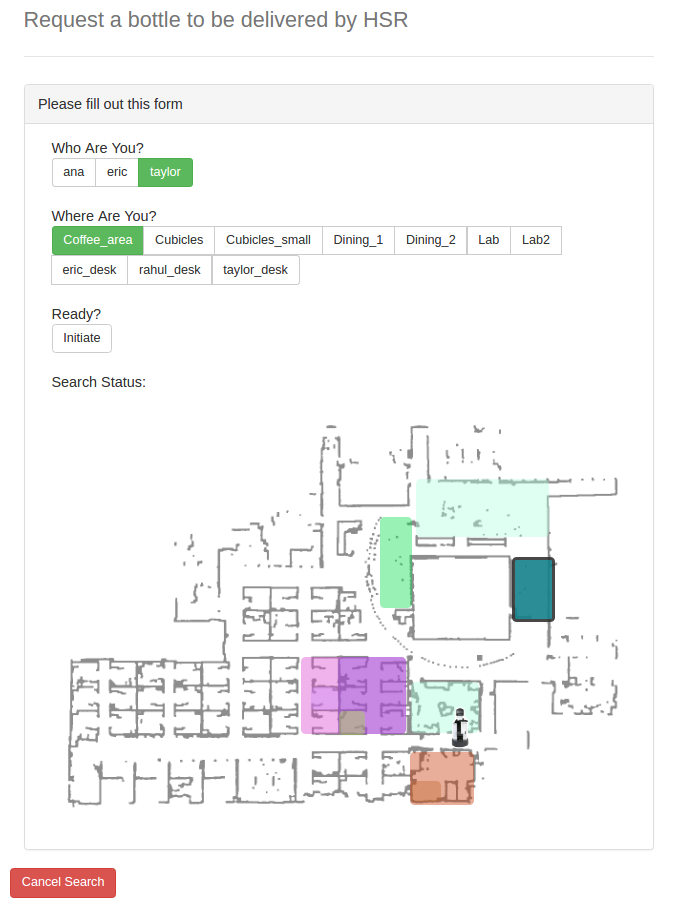

Toyota Robotics Work - 2016-2017

At Toyota Infotechnology Center I helped a researcher explore concepts of person recognition with mobile manipulators. As a ROS software engineer I wrote C++ code to control the robot based on sensor data, implemented custom physical search algorithms with the robot, modified ROS topics from proprietary modules to overcome some design limitations of the robot, and built an end to end demo including a robot-compatible bottle dispenser that allowed a person to request water delivery via a mobile web page.

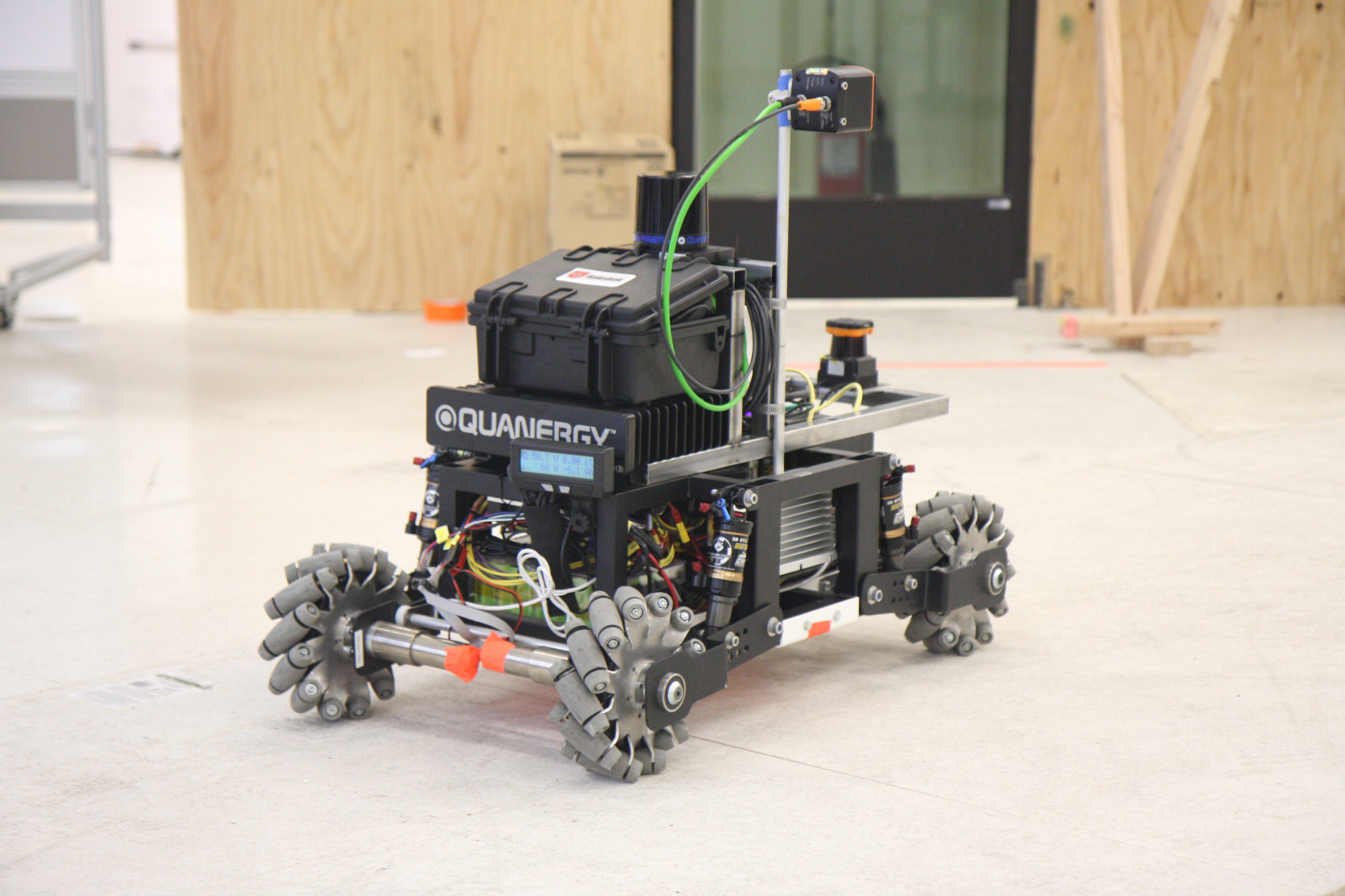

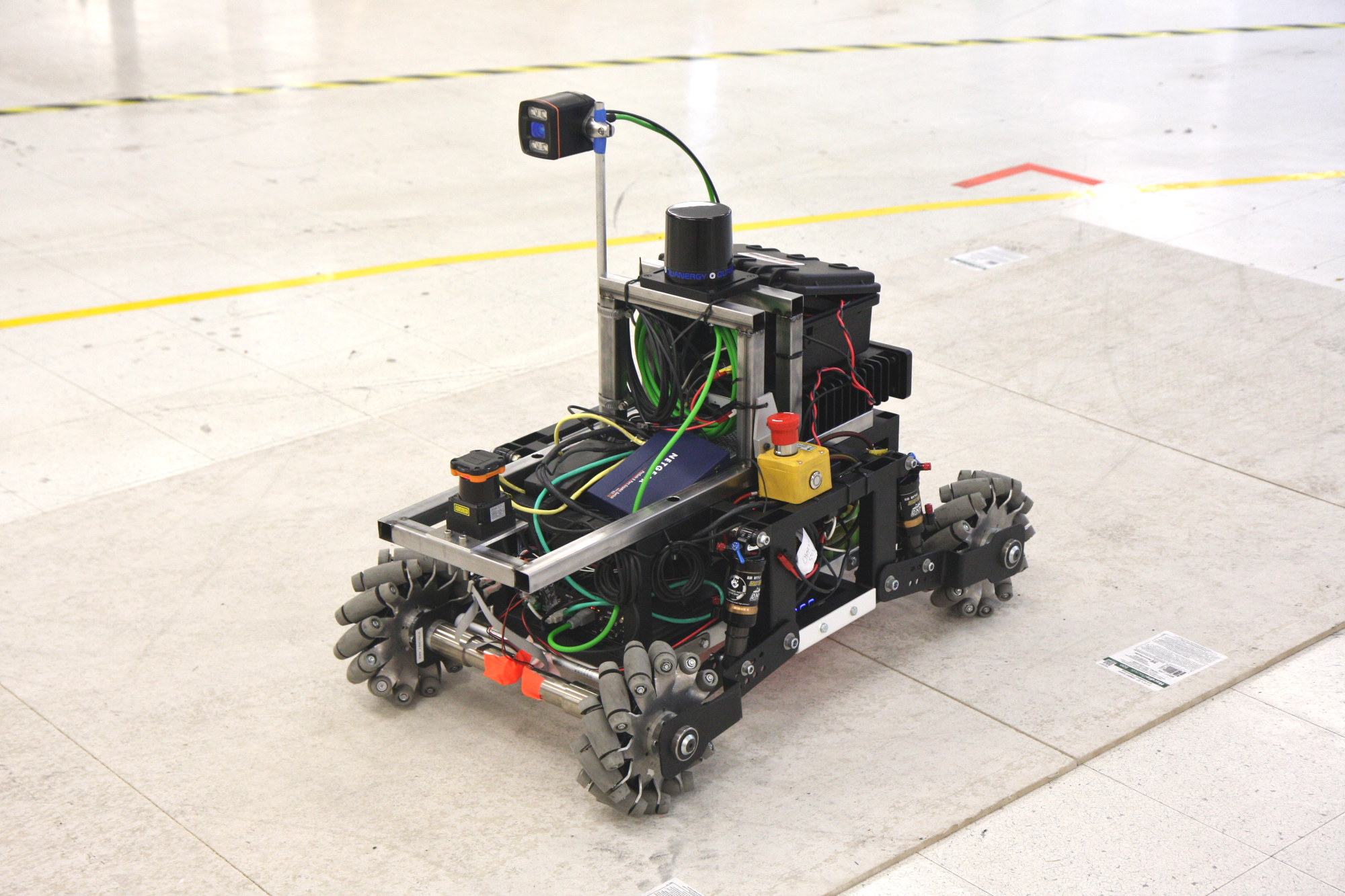

Snackbot project - 2015-2016

In 2015-2016 I was robotics software engineer on a project for Google Food to explore kitchen restocking using holonomic robotic shelving units. I worked on a small team of ROS software engineers and served as the software team liason to the hardware team on the same project.

3D Printed Snap Together Remote Control Car - 2014

I designed two versions of a 3D printable remote control car to check my assumptions about 3D printed robotics. It does seem, from what I have learned with Scout, that useful robots can be made on a home 3D printer. Additionally, it seems that a wide range of mechanisms can be produced on a home 3D printer without support material. Even with the additional constraint of screwless design, Scout was relatively easy to design. I am confident that a range of ground vehicles, stationary robotic assemblies, and boats could be made on a home 3D printer, opening up the possibility for rich open source robotics projects supported by a wide community. Find more information about Scout on its GitHub page. See also the article on Scout I wrote for Make Magazine.

Flutter Wireless - 2013-2018

I've designed all the PCBs for my company, Flutter Wireless. The main boards, the Pro and the Basic, feature a 64MHz ARM processor, lithium battery charger chip, cryptographic keystore, and 868/915MHz wireless radio with 1km range.

During that time I designed more than a dozen PCB designs for Flutter. All of Flutter's products are open source. Find more information at FlutterWireless.com

Brushless Motor Driver - 2016

As a hobby project and part of my goal to continue research in open source hardware for robotics, I designed a 1kW Brushless Motor Driver.

Source files are on github.

Brushless Linear Motors - 2010-2012

I designed and built several generations of brushless linear motors for my first attempt at a robotics business. This involved implementing work found in a research paper as a proof of concept, designing my own motors in simulation, and then building four generations of my own design. I also designed several generations of drive and control electronics, devised a novel non-contact position sensor, wrote the control software in C++, fabricated all mechanical parts myself including an aluminum housing with thin walls and complex 3D curves, wound the coils by hand, and assembled all PCBs.

Rugged Touch Screen Tablet and Load Monitoring Software - 2010

I designed a touchscreen tablet from scratch, combining a 400MHz SOC running Windows CE, a 7" 800x480 TFT Display, and a 7" capacitive touch panel with a custom machined housing and custom C# GUI application to create a complete load monitoring system for a customer's specialized application. I did all system bring up, including hand wiring of a 40 pin ribbon cable to prototype the display connection. I wrote all software for the system including the application loader and main GUI app with SQLite database, and machined the custom housing.

2000 Ft-Lb Underwater Torque Sensor - 2008

This torque sensor for the oil and gas industry is waterproof up to 4000m of depth, and features a pressure sealed display that can withstand 10,000 psi for over 24 hours.

I designed and machined all of the aluminum and steel components. This includes lathework on the 7" diameter bucket before and after welding to the machined top plate. The features on the side of the bucket were machined on a vertical mill using a 4th axis. The aluminum display also features a machined stainless steel support for strength.

Other 3D Printed Robots - 2012-2014

I've been exploring the concept of print-at-home robotics for several years. Some of the robots I have designed are shown below.

Before Scout V2, there was Scout V1

Before Scout V2, there was Scout V1

Scout V1's right angle gears didn't last long. Scout V2 uses all straight spur gears which seem to never wear out! Scout V1 was the first fully functional snap together robot I built, but it still needed some tape to keep the top on.

Scout V1's right angle gears didn't last long. Scout V2 uses all straight spur gears which seem to never wear out! Scout V1 was the first fully functional snap together robot I built, but it still needed some tape to keep the top on.

My initial work in using o-rings as pulleys (below) was not a success. O-rings stretch over time and will not stay tight. I'd like to make a good turtle bot some day.

My initial work in using o-rings as pulleys (below) was not a success. O-rings stretch over time and will not stay tight. I'd like to make a good turtle bot some day.

Other Machining Work - 2006-2013

My daily job for 7 years was to design custom torque measurement equipment and program our CNC machines to make it. Over the course of that time I designed hundreds of parts. Following is a small selection of some of the work I did there. Unless otherwise mentioned, I designed and machined all of the milled and lathed parts in the following photos. I also took all photos.

Offshore Torque Measurement System

Torque Wrenches

Fancy Box

3000 Fl-Lb Rotary Torque Sensor with angle output for Boeing

Bench Mount Torque Measurement Systems

"Rundown Fixture" and Custom Bolts

High Torque Test Stands